Conveyors

Conveyors exercises

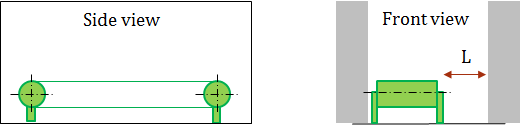

C-1. Design for constrained space

Design drive system for the conveyor situated in a narrow passage. L = 120 cm (see the sketch).

Fig.1. Explanation for the

task.

Fig.1. Explanation for the

task.

Available information:

- One drum to be driven

- No overloads, duty cycle - 100%

- Dusty environment, abundant heat removal capability, wet floor

- Grid 400 V

- Distance between the driven drum of the conveyor and the FC (cable length) - 30 m

- Rated torque 10 kNm

- Speeds: min - 200 rpm, max - 250 rpm

- Cooling water available

Design for: (A) Design system for lowest cost. (B) Design system for highest efficiency

C-2.Design for applications with different duties

Design drive system for the three conveyors with different duties (a) duty 100%, (b) 70%, (c) 50%. Duty cycle period - 1 min.

Available information:

- One drum to be driven

- Rated torque 50 kNm

- Speeds: min - 75 rpm, max -150 rpm

- No overloads

- Air-conditioned clean power house, abundant heat removal capability

- Grid 400 V

- Distance of conveyor from FC (cable length) - 40 m

- Cooling water not available

Use helical gearbox with ratio 1:5.

Summarize the data in a table like the one below. Explain the results.

| Case | Duty | Motor type | FC type | Cost motor | Cost FC | Cost total |

|---|---|---|---|---|---|---|

| 1 | 100% | |||||

| 2 | 70% | |||||

| 3 | 50% |

C-3.Design for applications with different overloads

You are chief engineer at a plant. Design drive system for the five conveyors. Design for the following overload variants:

- (a) No overloads (0%),

- (b) 100% 2 sec each 1 min,

- (c) 100% 1 min each 10 min,

- (d) 100% 2 min each 20 min.

- (e) 50% 1 min each 10 min.

Available information:

- One drum to be driven

- Rated torque 10 kNm

- Speeds: min - 400 rpm, max - 630 rpm

- Duty 100%

- Air-conditioned clear power house, abundant heat removal capability

- Grid 400 V

- Distance pump from FC (cable length) - 40 m

- Cooling water not available

Explain the results.

| Case | Overload | Motor type | FC type | Cost motor | Cost FC | Cost total |

|---|---|---|---|---|---|---|

| 1 | No | |||||

| 2 | 100% 2 sec each 1 min | |||||

| 3 | 100% 1 min each 10 min | |||||

| 4 | 100% 5 min each 20 min | |||||

| 5 | 50% 1 min each 10 min |

C-4. Design for lowest system cost

Design drive system for the four conveyors with different speeds (the same power).

Given parameters:

- No overloads

- Duty - 100% (uninterruptible operation)

- Location/environment - clean room

- Grid - 690 V

- Cooling water not available

- Speeds and torques according to the table:

| Case | speed, rpm | torque, kNm |

|---|---|---|

| 1 | 100...500 | 10 |

| 2 | 300...500 | 10 |

| 3 | 20...100 | 50 |

| 4 | 70...100 | 50 |

Design for: lowest investment cost (CAPEX). Assume energy efficiency is not important. Present total system efficiency at 100% load, 50% load

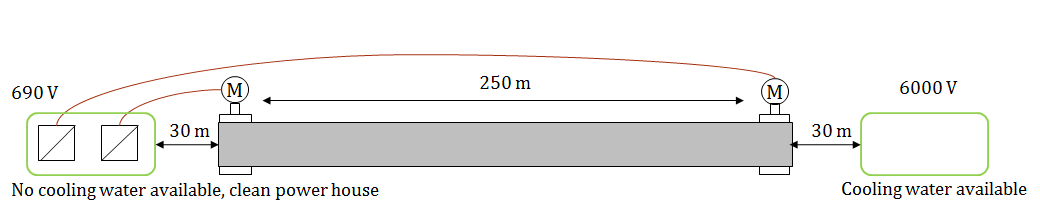

C-5. Design for long and short cables

Design drive system for the conveyor with two drums to be driven. Load sharing 50/50%. You are free to choose where the drive and the transformer (if any) will be located. Also free to choose voltage level.

Note: only one possible variant is shown on the sketch in Fig.1.

Fig.1. Explanation of the

task.

Fig.1. Explanation of the

task.

Available information:

- Rated torque 60 kNm (for the total conveyor)

- Operational speeds 40 - 200 rpm

- 20% overloads

- Duty cycle - 100%

- Choose between two power houses with 6000 V and 690 V voltage sources

- Power houses: constrained space (try to minimize footprint)

Design the system for lowest cost.