Ambient and coolant temperatures

When the component is expected to work at high ambient temperatures de-rating factors should be applied when choosing rating of the machine. Different equipment providers give slightly different derating factors. Some variants are presented in the tables 1 and 2. In DriveConstructor derating is done automatically when the user sets the ambient- or the coolant temperature for the components.

Ambient temperature

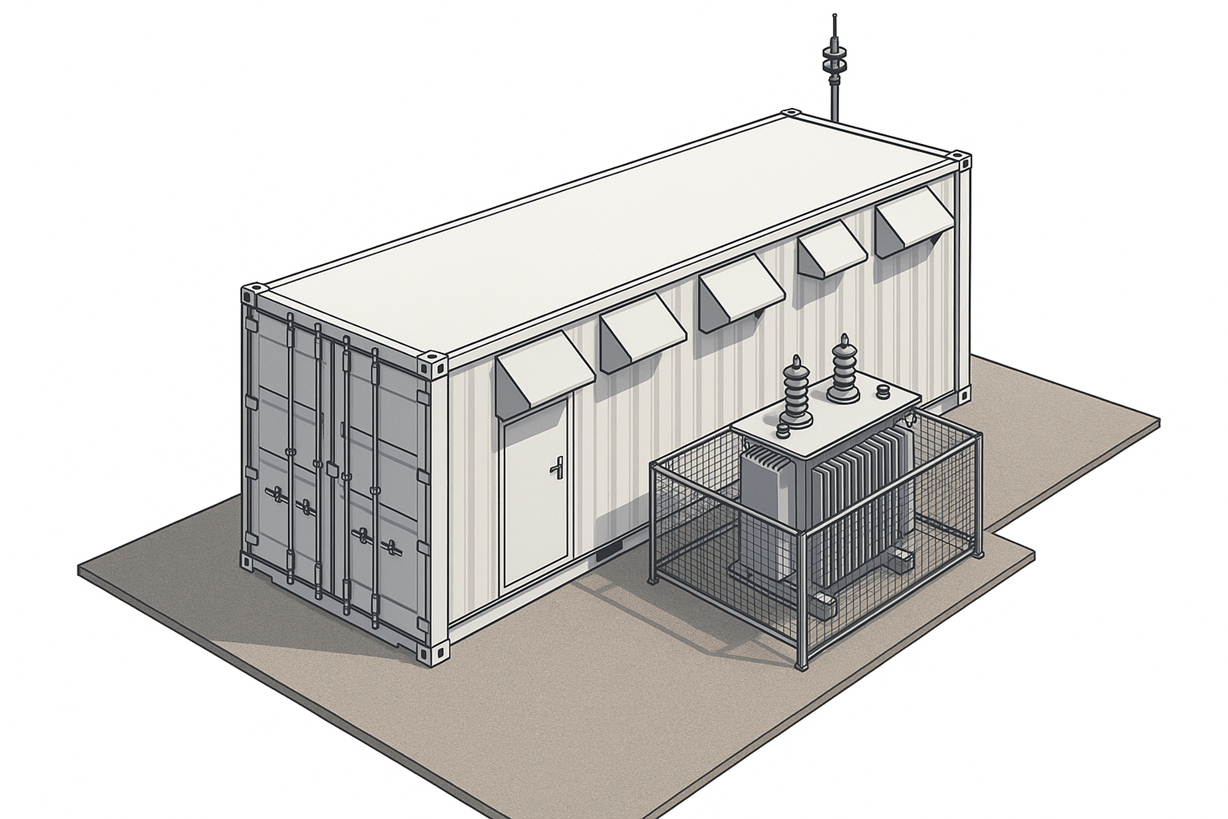

As the cable between the machine and the converter can be long (in special cases up to several km!) the environment can be quite different for the machine and the converter, as well as for other components of the system. The machine for example can be at the open air while the converter in a dry electric room with air conditioning or a container (Fig.1).

Fig.1. Container

example.

Fig.1. Container

example.

The coefficient of power derating with ambient temperature is defined as permissible output in % of rated output as function of ambient temperature .

Table 1. Air-cooled components. Power derating as function of ambient temperature.

| Electric machine & Transformer | Frequency converter | |

|---|---|---|

| 30 | 108% | 102% |

| 35 | 104% | 100% |

| 40 | 100% | 98% |

| 45 | 96% | 92% |

| 50 | 92% | 84% |

When the component needs to be de-rated for both temperature and altitude, the de-rating factors given in the table should be multiplied together.

Coolant temperature

Temperature of the cooling water at the input of the component cooling circuit. In DriveConstructor it can be varied in the range 20...50 for EM, FC and transformers. The coefficient of power derating with coolant temperature is defined as permissible output in % of rated output as function of coolant temperature .

Table 2. Water-cooled components. Power derating as function of coolant temperature.

| Electric machine | Frequency converter | Transformer | |

|---|---|---|---|

| 20 | 110% | 105% | 105% |

| 30 | 108% | 104% | 104% |

| 35 | 104% | 100% | 100% |

| 40 | 100% | 92% | 100% |

| 45 | 96% | 84% | 96% |

| 50 | 92% | 76% | 92% |

When a component, like liquid-cooled FC, has both air- and water-cooled parts, derating should be calculated for both parts of the respective ambient- and coolant temperatures. In addition derating for altitude (if needed) should be implemented. Smallest of the products and should be taken as the overall overload. For example if =90% and =80%, the product is 0.9*0.8=0.72 or 72%.

Temperature of the coolant may help to solve the high-altitude problem. It is possible to compensate high altitude with lower temperature of the coolant.

There is also PWM frequency derating, though this functionality is not included in DriveConstructor.