Gearboxes

A gearbox uses combinations of cogwheels to provide speed and torque conversions from a rotating power source to another device. Each gearbox is characterized by gear ratio which is defined as the input speed relative to the output speed. Gear ratio can be related to one stage in the gearbox or to the whole gearbox if the latter consists of more than one stage. Overall gear ratio is a product of ratios of all stages. Also overall efficiency is a product of efficiencies of all stages.

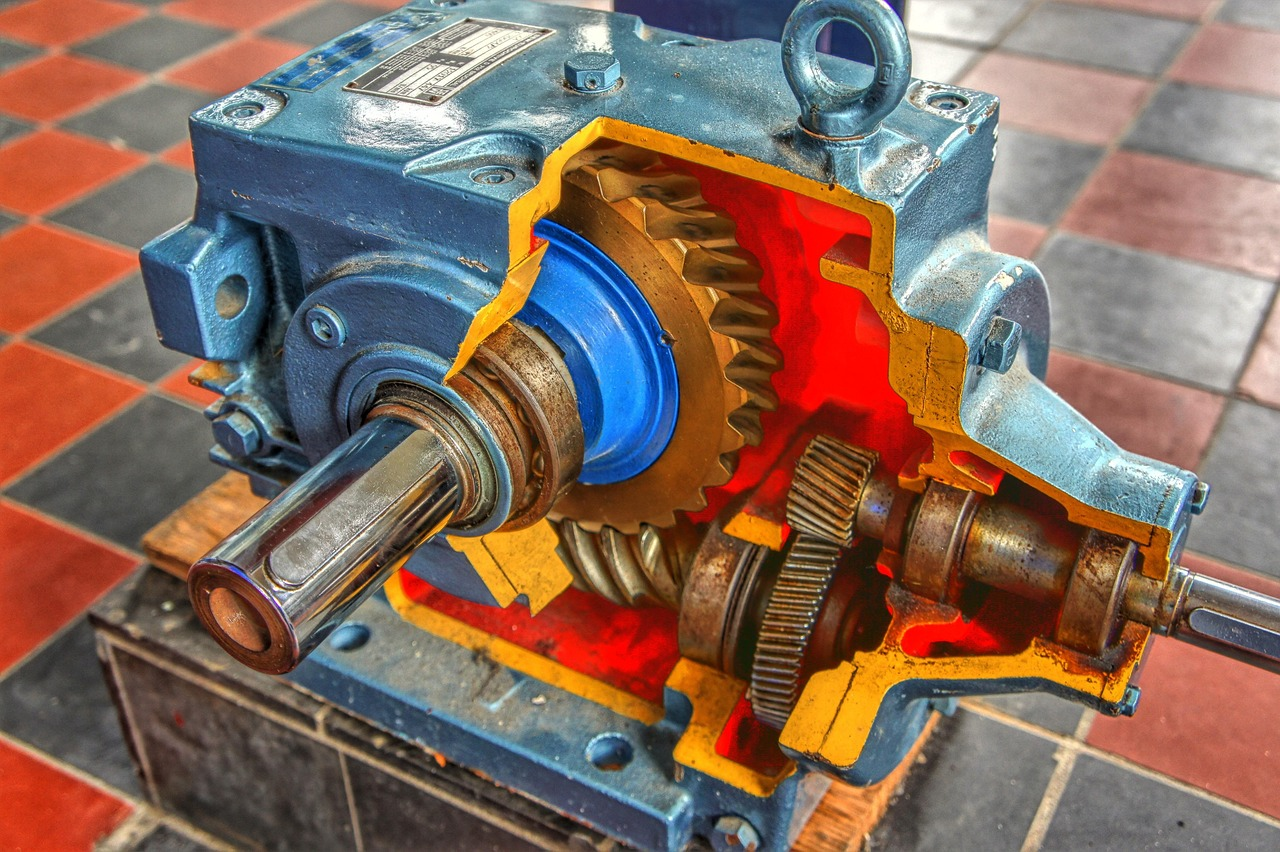

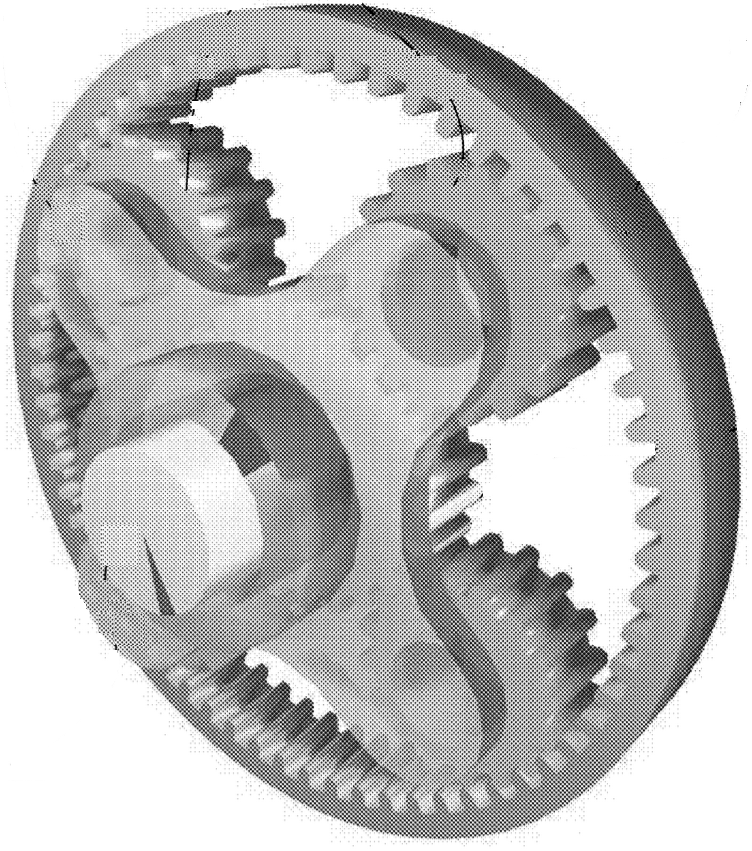

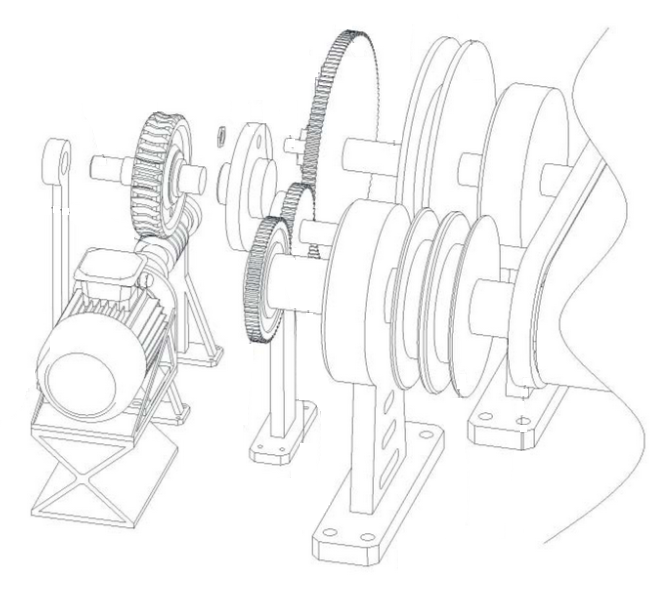

FIg.1. Gearbox

example.

FIg.1. Gearbox

example.

In DriveConstructor gearbox can have maximum three stages. However, in the real world some gearboxes may have more than three stages.

When choosing a gearbox the designer should remember service factors, take account of the number of starts, impact loading and the like. Typical procedure of gearbox selection includes the following steps:

- Choose gear type

- Choose transmission ratio ("gear ratio")

- Determine the nominal power rating of the gear unit

- Check for maximum torque, e.g. peak operating, starting or braking torque

- Check additional forces

- Check thermal capacity (derating due to ambient temperature)

- Check mounting (all parts to be lubricated should be lying in the oil or be splash-lubricated)

In DriveConstructor this procedure is present in a simplified version.

Stage types

Stages may be of different types as is presented below. In one gearbox there can be combined stages of different types.

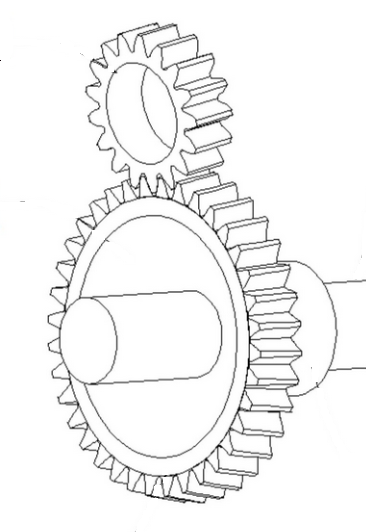

Helical

Helical stage is presented in Fig.2. Gear ratios for helical gear stage can be in the range of 1,5...10. In DriveConstructor we narrow the possibility to choose from to 3...8. Efficiency of helical gear is high - usually between 97 and 98%. In DriveConstructor we assume rated efficiency of 98%. This type of gear is cheap to manufacture and has good torque and noise properties, though it is generally expensive and requires many gear stages for large reductions.

Fig.2.

Helical stage.

Fig.2.

Helical stage.

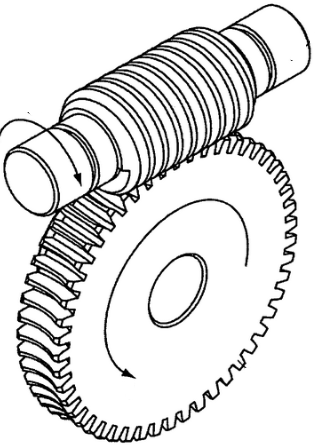

Fig.3. Worm gear.

Fig.3. Worm gear.

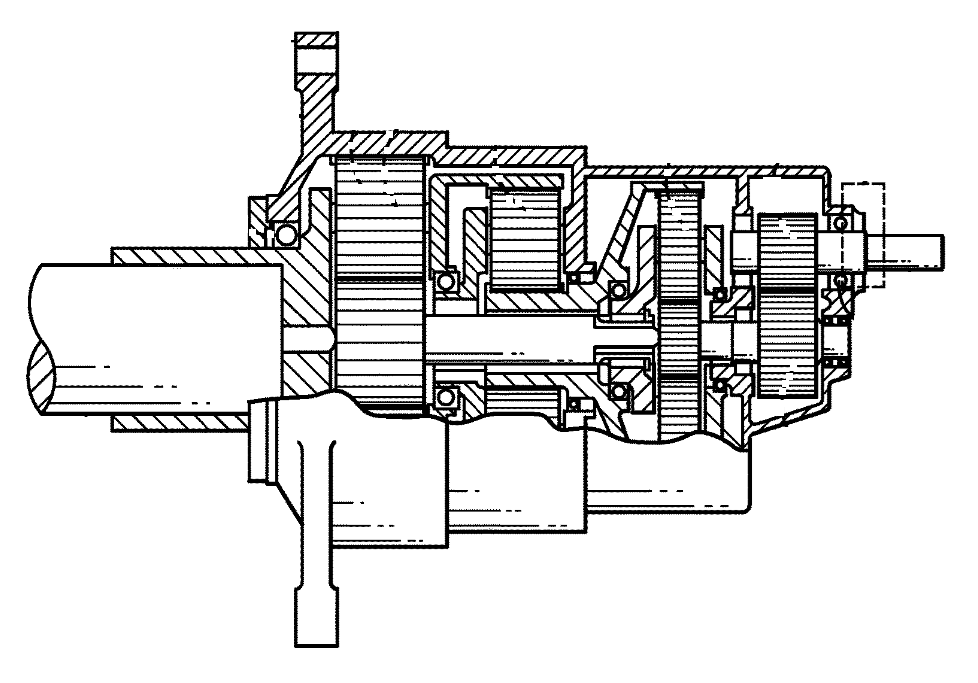

Worm gear

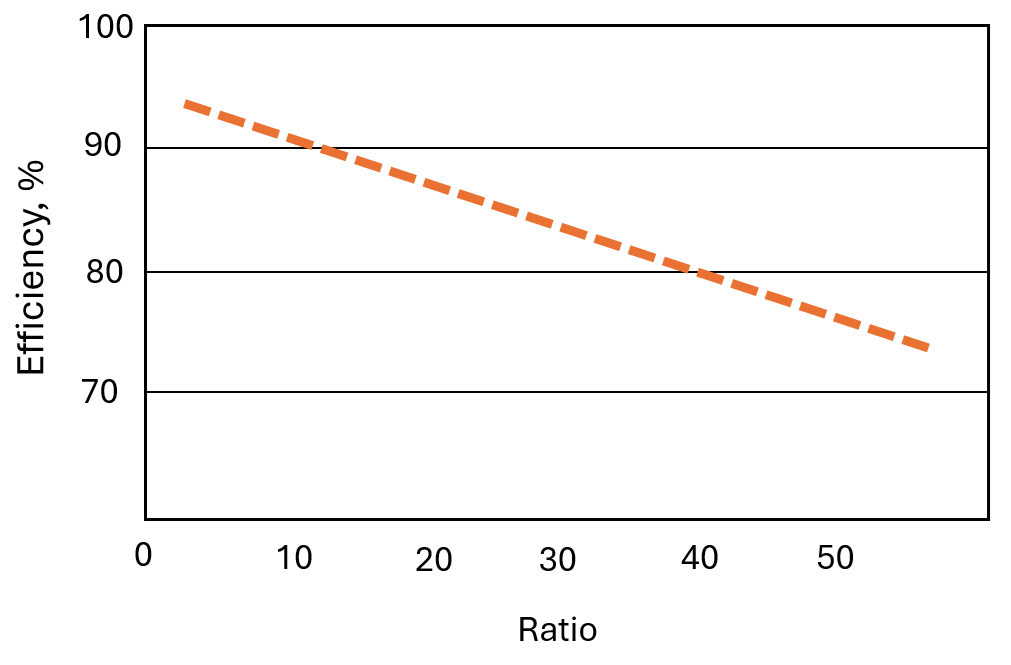

Worm stage is presented in Fig.3. Gear ratios for worm stage can be from 5 and up extremely high ratios (100!). In DriveConstructor we narrow the possible to choose from to 10...40. Efficiency of worm gears goes down with the increase of the ratio (Fig.4). The possibility to have very high transmission ratios translates into greater cost-effectiveness. Also, worm gears typically ensure quiet, vibration-free operation. They are inherently a right-angle drive. Their typically low efficiency suggests their use for low or middle-to-low power demand applications and/or those featuring intermittent duty. They can be ideal for applications that need to resist reversing.

Fig.4.

Efficiency of worm gear for different ratios.

Fig.4.

Efficiency of worm gear for different ratios.

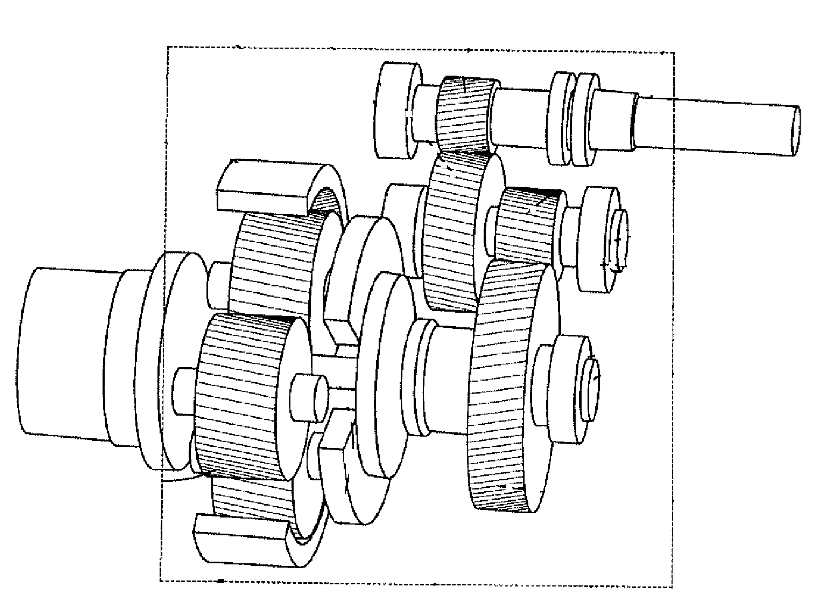

Planetary gear

Planetary stage is presented in Fig.5. Gear ratios for planetary stage can be in the range of 3...10. In DriveConstructor we narrow the possibility to choose from to 4...8. Planetary gears can handle large reductions and give huge torque capability. They have high efficiency and are very compact. At the same time such gears are expensive to manufacture and can be noisy at high speeds.

Fig.5.

Planetary stage.

Fig.5.

Planetary stage.

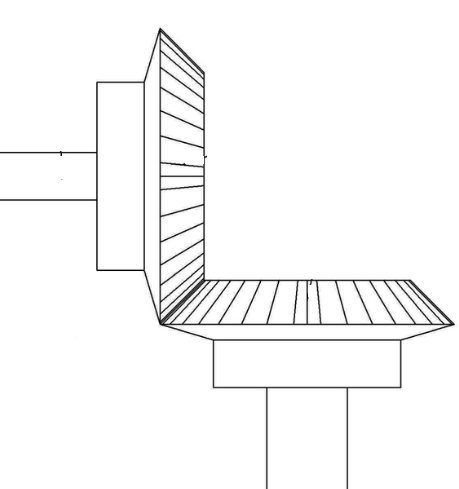

Fig.6. Bevel

stage.

Fig.6. Bevel

stage.

Bevel gear

Bevel stage is presented in Fig.6. Gear ratios for bevel stage can be in the range of 1,5...4. In DriveConstructor we limit the choice to 2...3.

Combinations of stages

The stages can be put together in various combinations. Some examples are presented below.

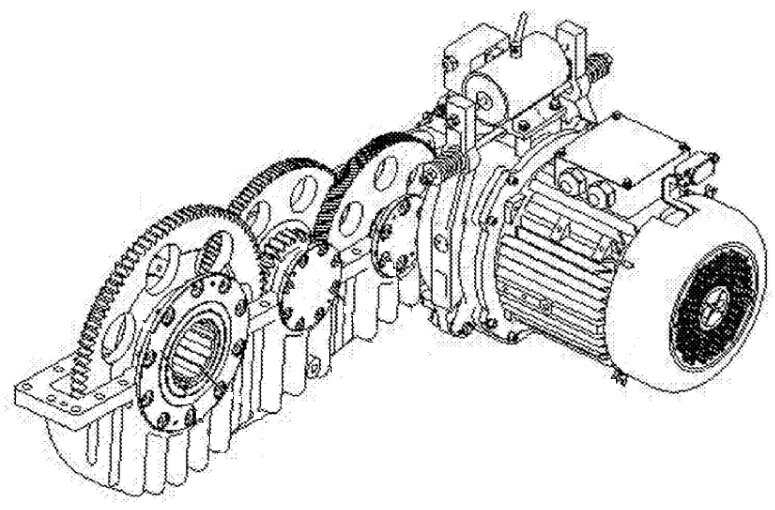

Gearboxes comprising several helical stages (Fig.7) are used generally in heavy-duty applications. They are quite efficient and can have many stages.

Fig.7.

Gearbox with 3 helical stages and a motor.

Fig.7.

Gearbox with 3 helical stages and a motor.

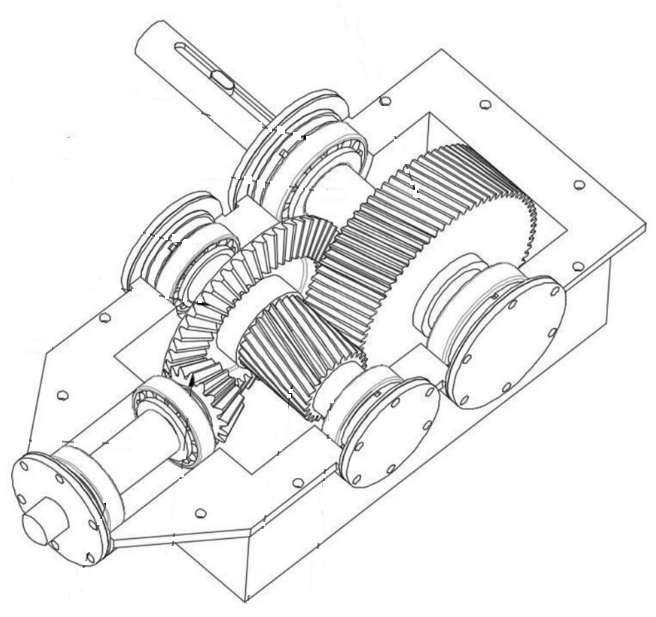

In the configuration presented in Fig.8 the input and output shafts are arranged at right angles via a gear set with either intersecting (bevel helical) or non-intersecting (hypoid) axes. The right-angle helical design ensures great space efficiency interms of width, and provides the primary alternative to worm reducers in applications involving right angle drives. They are characterized by high efficiency and can extend to extremely high reduction ratios (even to 1700:1).

Fig.8. 1 bevel and 1 helical stage.

Some more examples are presented in Fig. 9-10.

Fig.9. Worm

gear and helical stages for conveyor drive.

Fig.9. Worm

gear and helical stages for conveyor drive.

Fig.10. Gearbox with one planetary and two helical stages for a wind turbine..

Fig.11.

Gearbox with three planetary and one helical stage for a wind turbine.

Fig.11.

Gearbox with three planetary and one helical stage for a wind turbine.

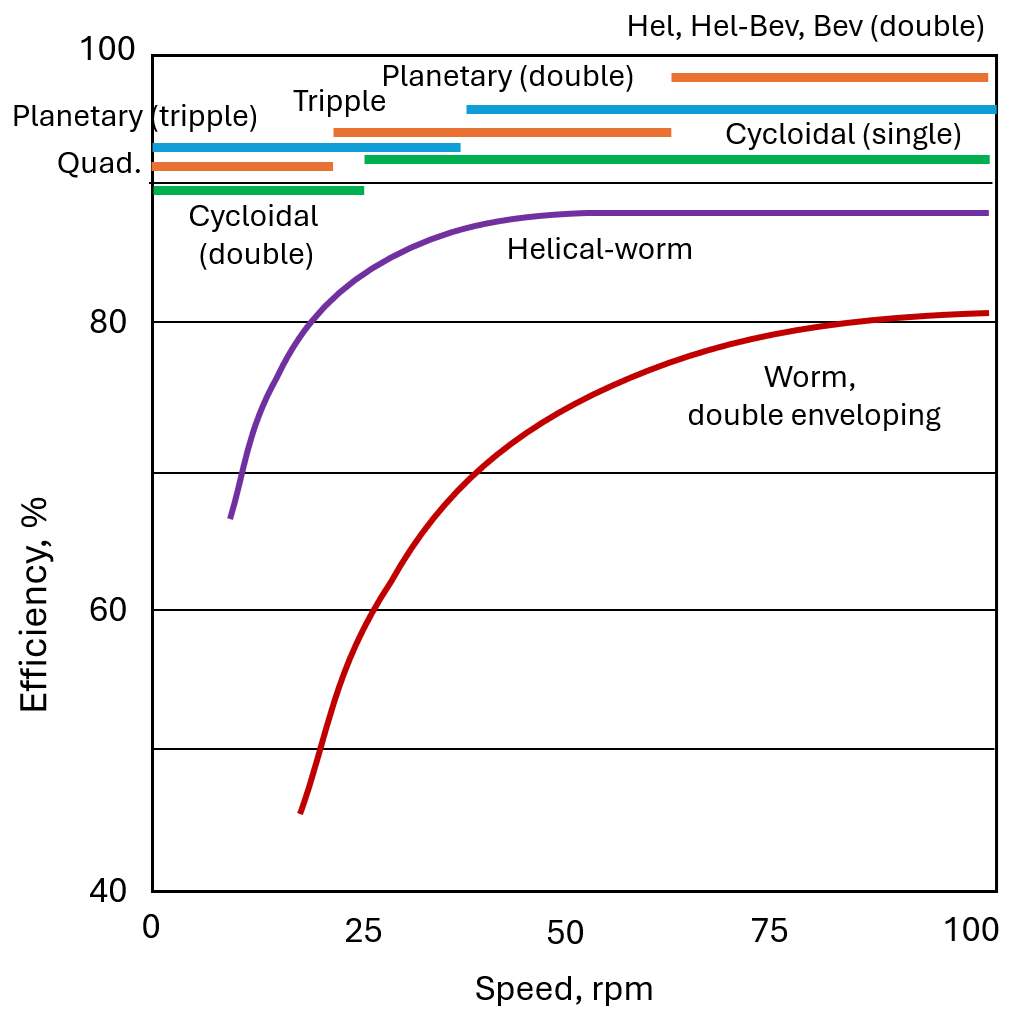

Efficiency of any combination is the product of efficiencies of the stages, therefore, efficiency of several stages is lower than single-stage solution. Fig.12 presents efficiencies of some combinations of stages. Note that lower rpm means higher gear ratio.

Fig.12. Efficiencies

of various combinations.

Fig.12. Efficiencies

of various combinations.